XEBEC Ceramic Stone™ Meister Finish

Optimal for polishing and deburring of molds and dies.

How to Use

For effective use

The use of metal polish liquid prevents clogging and increases polishing efficiency.

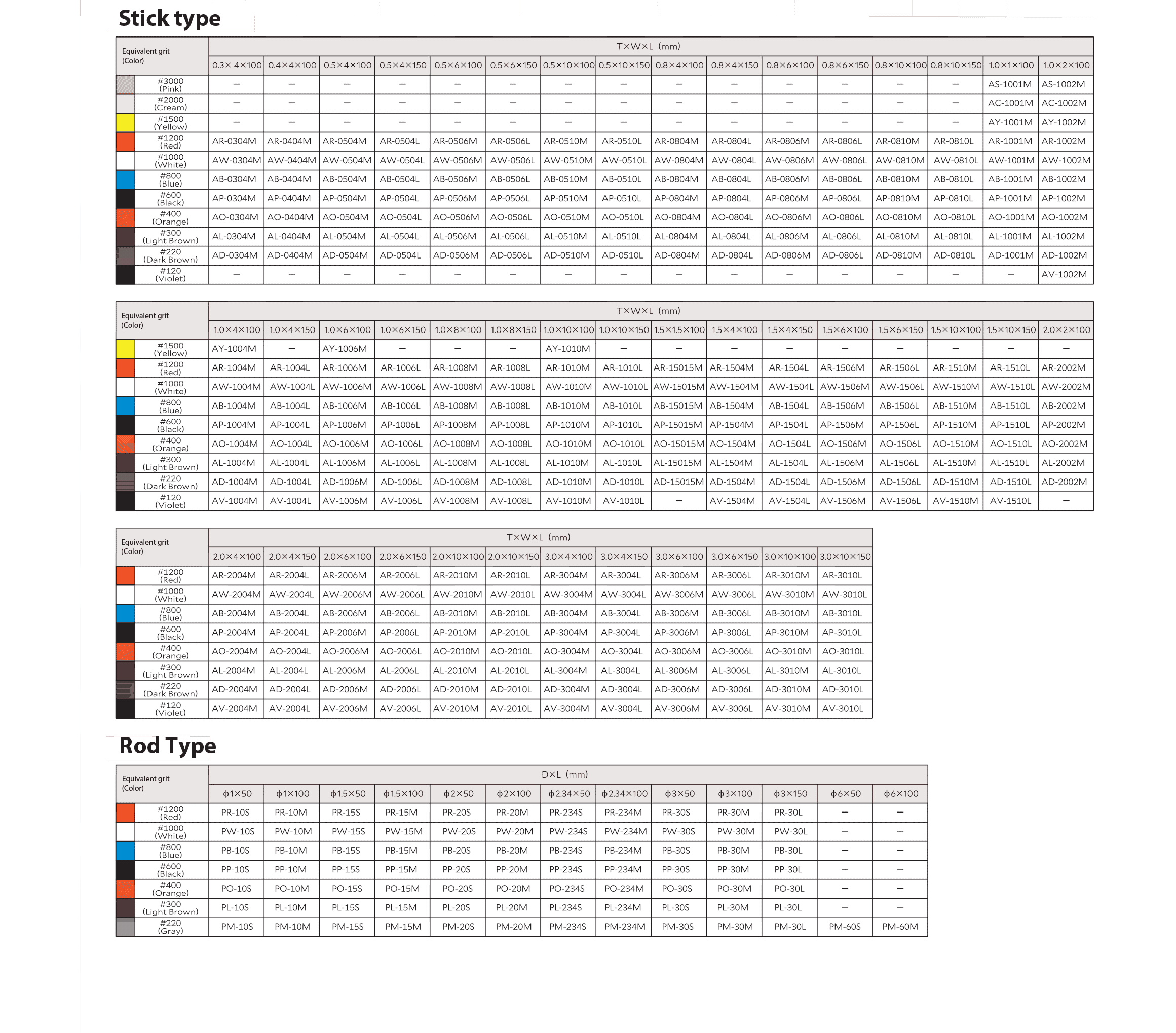

Stick type

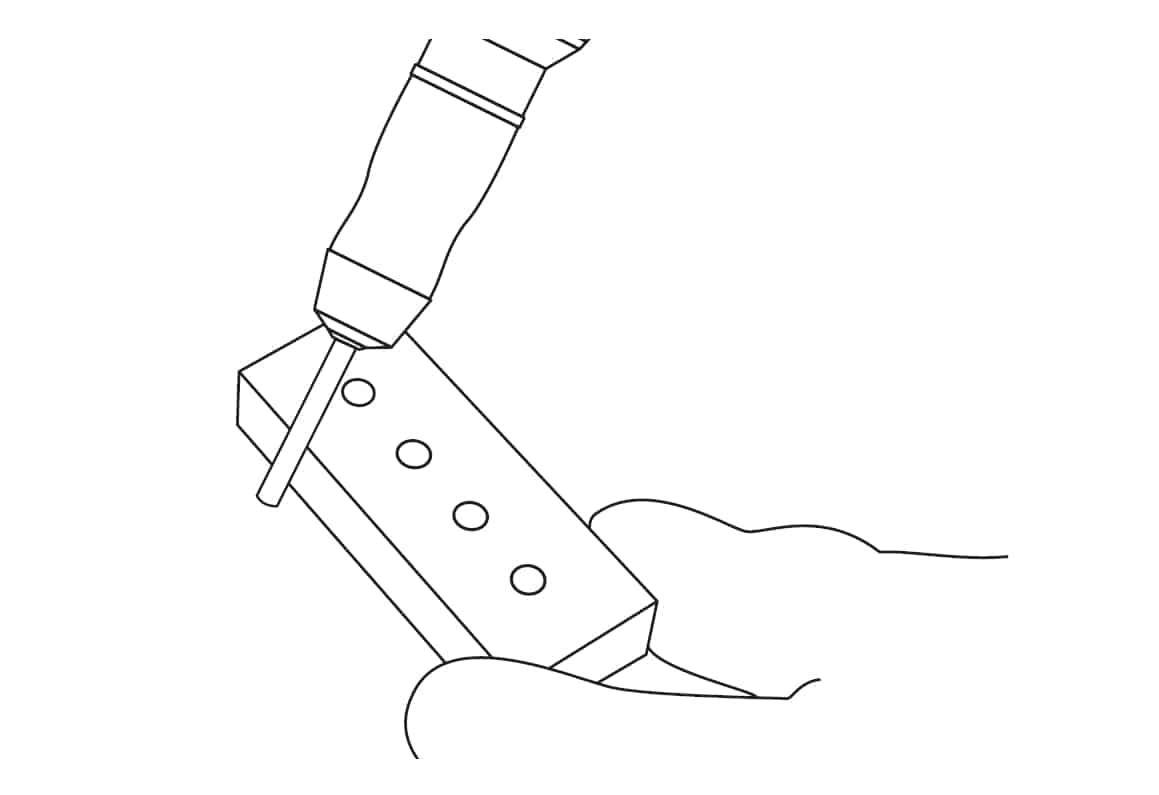

Press the tip against the surface at an angle of approximately 45 degrees.

*XEBEC Ceramic Stone Diamond contains diamond entirely, the side can be also used for polishing.

Rod type

The entire surface (tip and sides) has the grinding power.

The tool can be used by directly holding in your hand, or can be used with the optional stick holder to improve work efficiency.

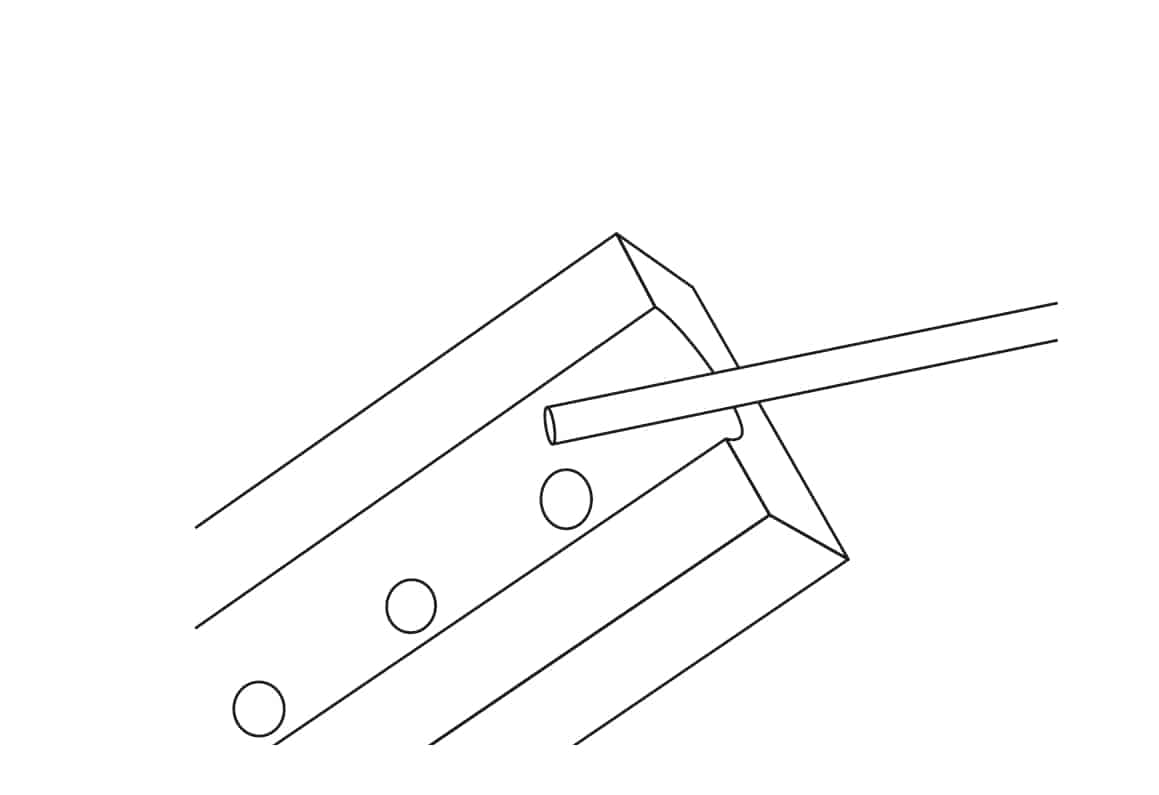

Stick type

Using with a vibratory tool (electric, ultrasonic and pneumatic) improves efficiency.

*When using with an ultrasonic vibratory tool, it is recommended to use the XEBEC Ceramic Stone Heat-Resistant, which is resistant up to 200℃.

*XEBEC Ceramic Stone Soft (BS-2006M) cannot be used with a vibratory tool.

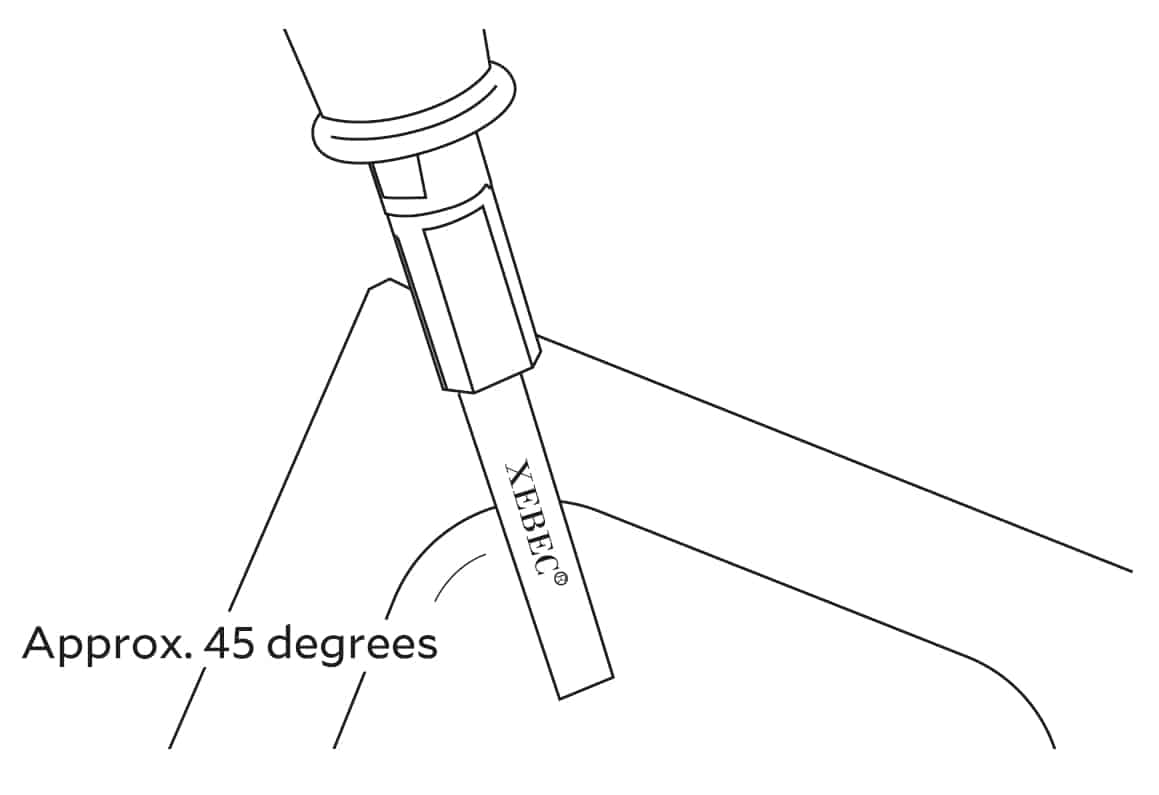

Rod type

Using with a rotary tool (electric and pneumatic) improves work efficiency.

When using rod type (φ2.34mm, φ3mm) with a rotary tool, use at less maximum rotational speed of 30000min⁻¹ and make a tool length less than 50mm.

*XEBEC Ceramic Stone Soft (PBS-30M) cannot be used with a vibratory tool.

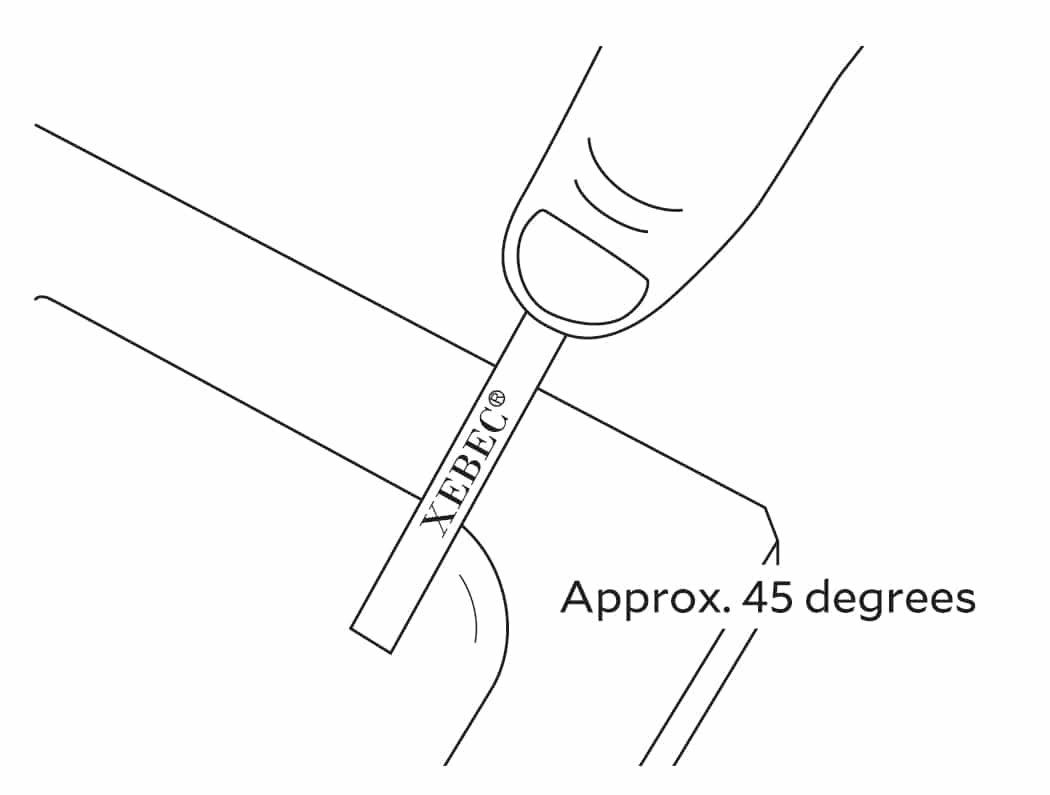

How to shape or form the tool tip

If the tip is worn out, form it with a diamond disc blade or grinder.

You can also customize the shape depending on the application or workpiece shape.

To shape the tip of the rod type finer, mount the tool on a rotary tool and rotate it for forming.

To cut off the tool, make a cut in both sides of the tool using a diamond disc blade etc.

For the details, please see the Maintenance page.

Maintenance

How to shape or form the tool tip

If the tip is worn out, form it with a diamond disc blade or grinder.

You can also customize the shape depending on the application or workpiece shape.

To shape the tip of the rod type finer, mount the tool on a rotary tool and rotate it for forming.

To cut off the tool, make a cut in both sides of the tool using a diamond disc blade etc.

Before processing, please read “Operation safety measures” below and follow it without fail.

Operation safety measures

Always wear protective goggles, gloves and masks when using the tool.

Wear long sleeves, tight cuff, and clothing to minimize skin exposure.

Cutting particles and burrs may scatter within the work area as the tools rotates.

Please stay clear of the area.

The area around your work is hazardous in case flying pieces of fiber rods from the tools and grinding powder may scatter.

Enclose your working area to prevent other people from entering or have them wear protective equipment as well.

Follow the precautions for use and operation safety measures without fail.

If you fail to observe them, there are following risks.

*A tool or a part of tool may crack, drop off, distort or break.

*Broken pieces of a tool or grinding dust may stick into your skin, or at worst stick into yours eyes, causing loss of sight.

*Dust generated by machining process may bring up skin irritancy or allergy.