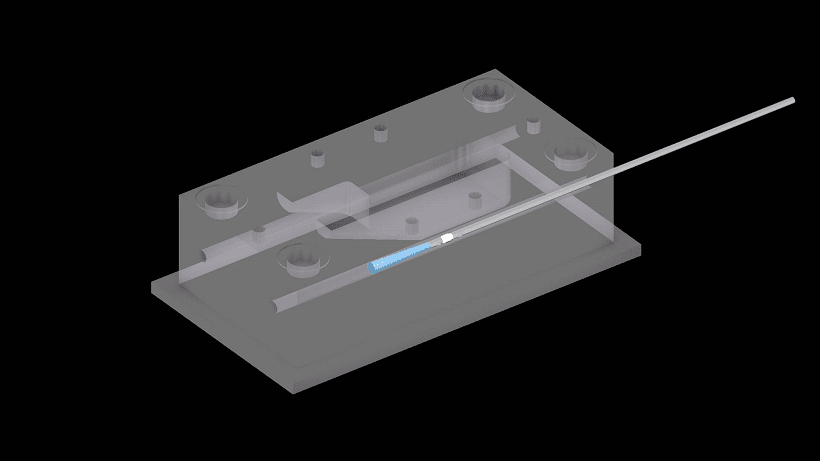

Mold (Cooling hole)

Before

| Tool |

Round bar grindstone |

|---|---|

| Problem |

It took time for manual use of rod grindstone. There was no tool reaching a deep hole of 300mm or more. Manhour required to make a custom-build shank in order to hold a grindstone. |

After

| Tool | XEBEC Brush Crosshole (CH-A33-7F) |

|---|---|

| Results | Stable finish quality in a shorter time realized. |

Workpiece information

| Industry |

Mold |

|---|---|

| Part name |

Mold (Cooling hole) |

| Material type |

SKD60 |

| Machining process |

Reaming |

Processing conditions

| Tool |

XEBEC Brush Crosshole (CH-A33-7F) |

|---|---|

| Details of processing |

Cooling hole polishing after reaming |

| Spindle speed (min⁻¹) |

12,000 |

| Table feed (mm/min) |

2,000 |

| Depth of cut (mm) |

– |

| Machining time (sec) |

– |