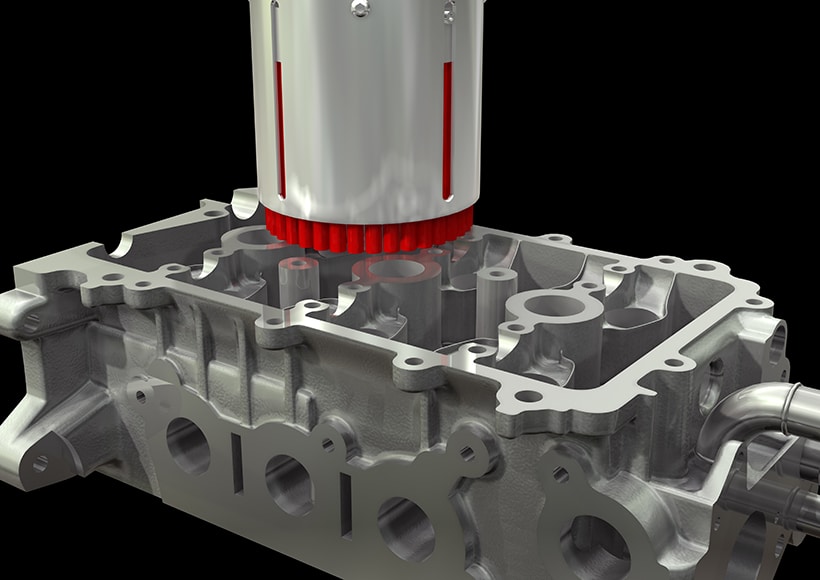

Cylinder head (Matching surface)

Before

| Tool |

Abrasive-impregnated nylon brush |

|---|---|

| Problem |

It took long hours for deburring and burrs still remained after processing due to low grinding power. Moreover, workpiece was stained by nylon brushes and man-hour is required for cleaning. |

After

| Tool | |

|---|---|

| Result |

Shorter cycle time was realized by high-feed processing. Coolant contamination was reduced to one third and man-hour for cleaning saved. |

Workpiece information

| Industry |

Automotive |

|---|---|

| Part name |

Cylinder head (Matching surface) |

| Material type |

ADC12 |

| Machining process |

Face milling processing |

Processing conditions

| Tool |

XEBEC Brush for Surface (A11-CB100M) |

|---|---|

| Details of processing |

Deburring of the matching surface after face milling process. |

| Spindle speed (min⁻¹) |

1350 |

| Table feed (mm/min) |

2000 |

| Depth of cut (mm) |

0.5 |

| Machining time (sec) |

– |