Ring-shaped internal gear

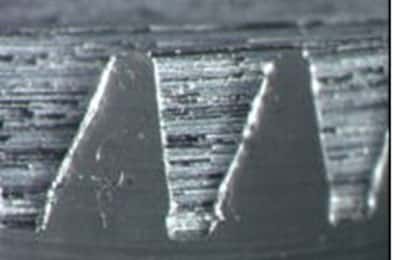

Before

| Tool |

File |

|---|---|

| Problem |

Metal filing handwork caused unstable quality. Complex shape of workpiece caused long lead time of deburring and high labour cost. |

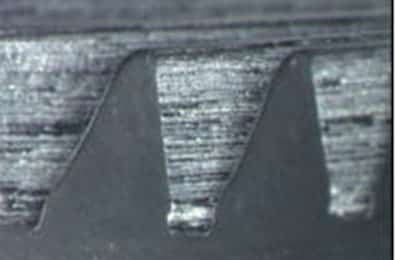

After

| Tool | XEBEC Brush for Surface (A11-CB40M) |

|---|---|

| Result |

Fully automated deburring introduced. Stable quality with shorter processing time as well as cost reduction realized. . |

Workpiece information

| Industry | Automotive |

|---|---|

| Part name | Ring-shaped internal gear |

| Material type | S45C |

| Machining process | Gear cutting |

Processing conditions

| Tool |

XEBEC Brush for Surface (A31-CB40M) |

|---|---|

| Details of processing |

Deburring the gear end face after gear cutting process |

| Spindle speed (min⁻¹) |

2,000 |

| Table feed (mm/min) |

– |

| Depth of cut (mm) |

0.5 |

| Machining time (sec) |

– |