Select By Problem

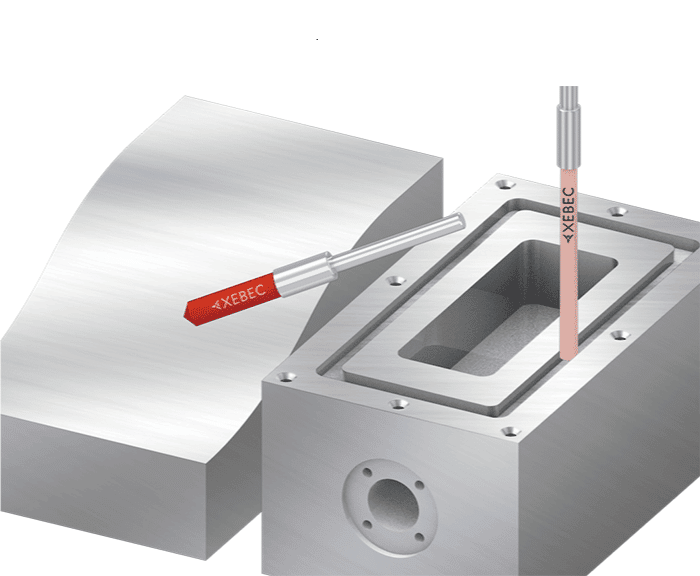

Select a tool depending on part profile and/or processing method prior to deburring.CNC deburring and polishing

-

Deburring after face-milling, end-milling and drilling

-

Cuter mark removal and polishing on surface

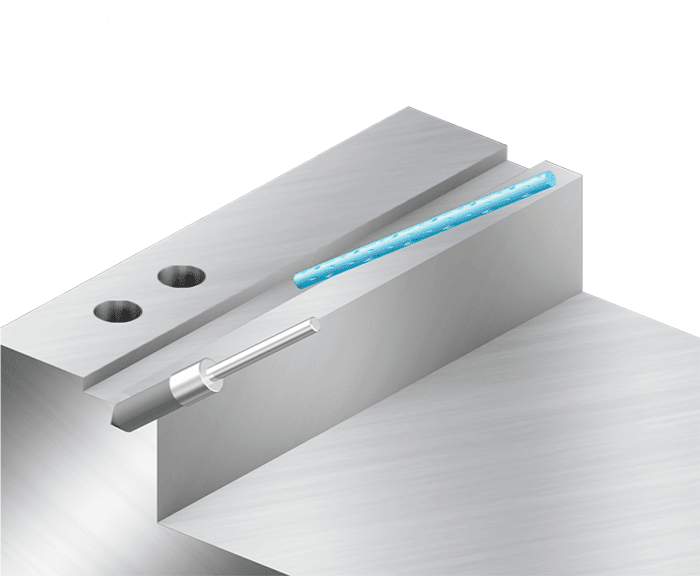

XEBEC Brush™ Surface

Ideal for deburring, cutter mark removal and surface polishing.

LINK

-

Deburring after end-milling, threading and drilling

-

Polishing on side surface and inner diameter

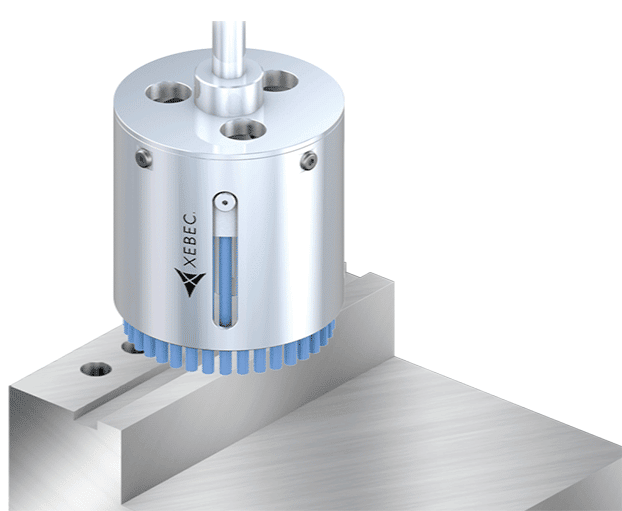

XEBEC Brush™ Wheel Type

Ideal for deburring and polishing the inner diameter, side surface and screw thread.

LINK

-

Deburring after drilling

-

Cutter mark removal and polishing on inner diameter

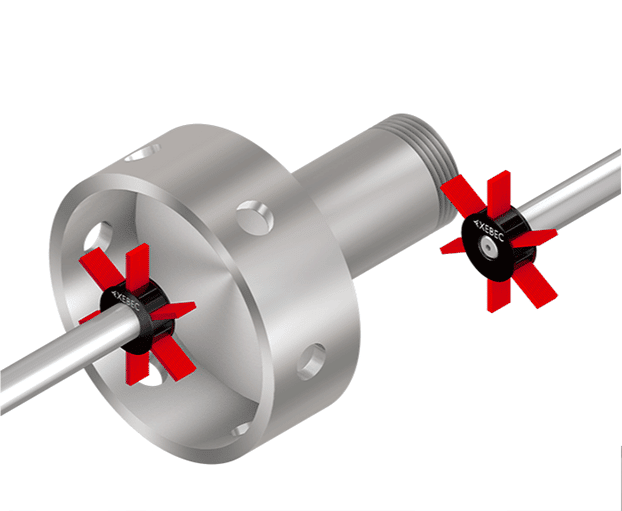

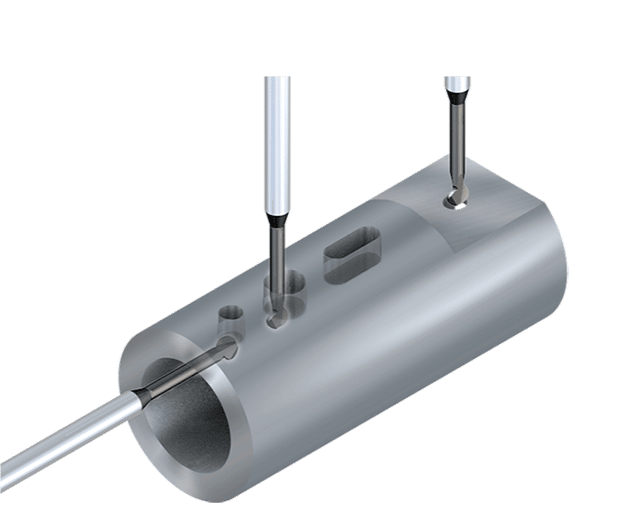

XEBEC Brush™ Crosshole

Ideal for deburring, polishing and cutter mark removal on inner diameter and counterbored part

LINK

-

Deburring after drilling

XEBEC Back Burr Cutter and Path™

Optimal solution for high-precision deburring of 3D-curved crossholes

LINK

Hand tools

-

Cutter mark removal and polishing on flate surface

XEBEC Brush™ Surface End Type

Ideal for cutter mark removal and polishing on the sealed surface

LINK

-

Hole deburring

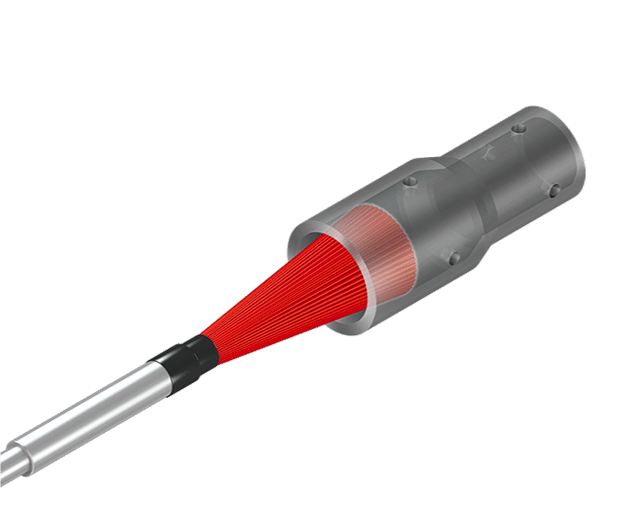

XEBEC Stone™ Flexible Shaft

Flexible shaft allows soft contact with a workpiece and suppresses subtle vibration when being processed. Ideal for deburring both front and back of a drilled hole.

LINK