XEBEC Brush™ Surface Extra-Large

Ideal for deburring, cutter mark removal and surface polishing with a width of 100mm or more

Applicable equipment

Machining center

Combined lathe

Special machine

Robot

General purpose lathe with milling function

Drilling machine

Rotary tool

(electric)

Rotary tool

(pneumatic)

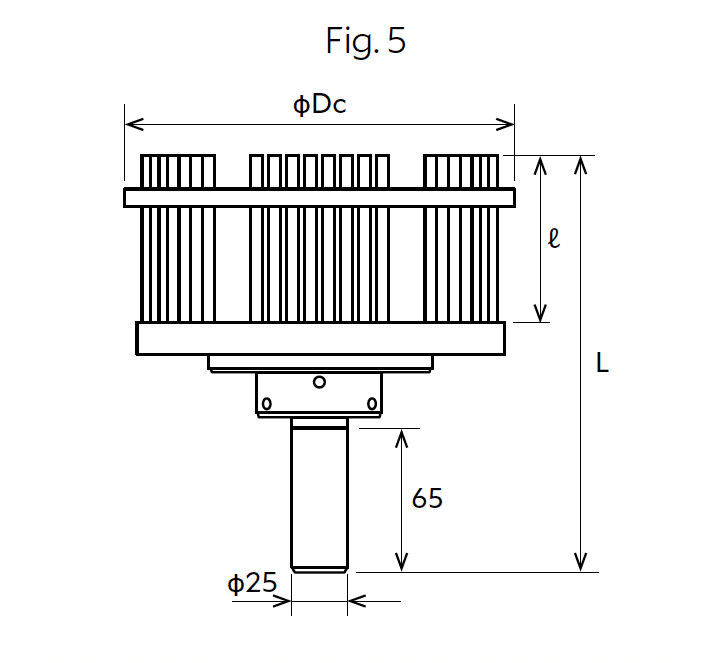

Tool composition

The brush main unit and the slide ring are separate items. Assemble the main unit and the slide ring before use.

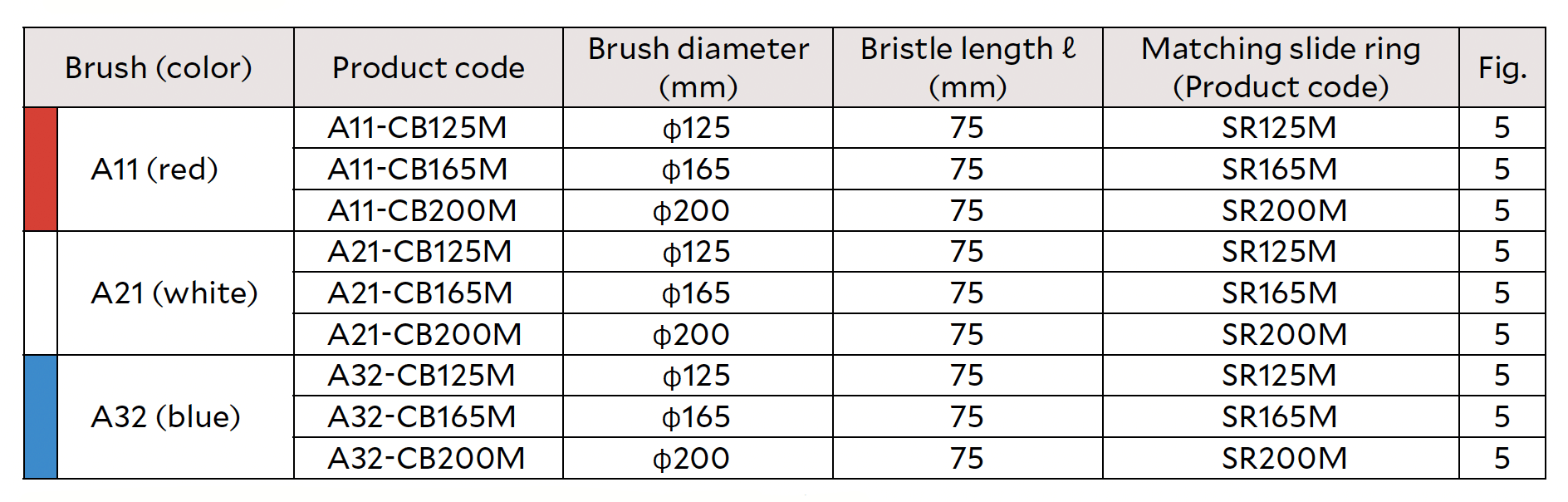

Brush

*The Brush size is approximate as the tip expands by rotating.

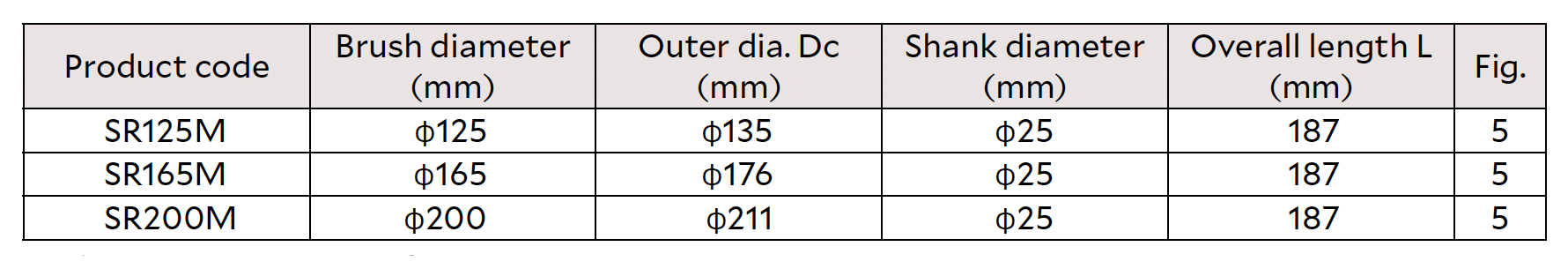

Slide rings

- The slide ring consists of a ring, base holder and shank.

- Base holder and shank sizes are the same for all brush diameters. Ring size varies with brush diameter.

- Combined weights of brushes and slide rings are: φ125: 1920 g, φ165: 2320 g and φ200:2750g.

How to use

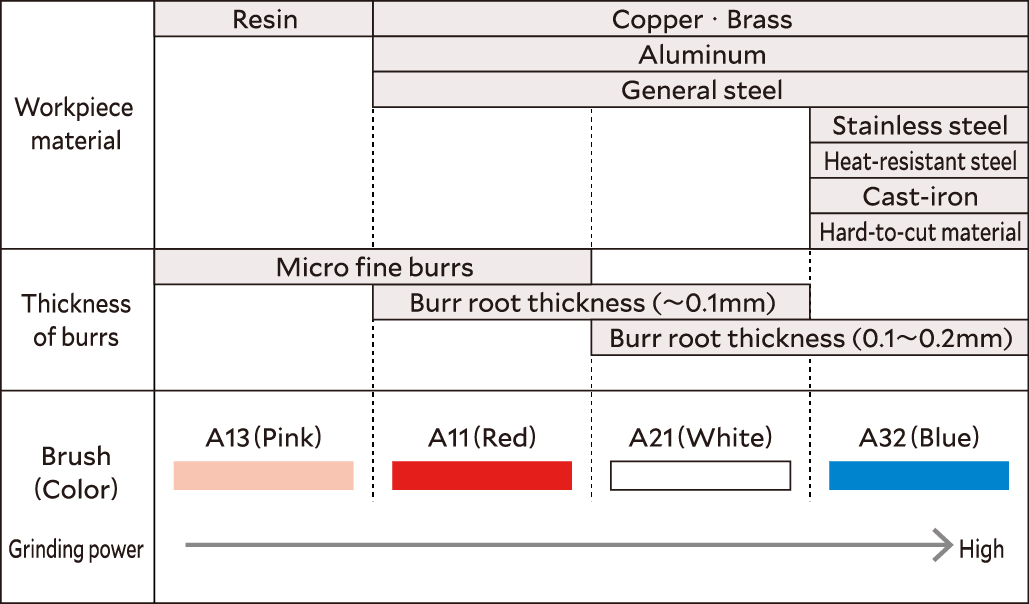

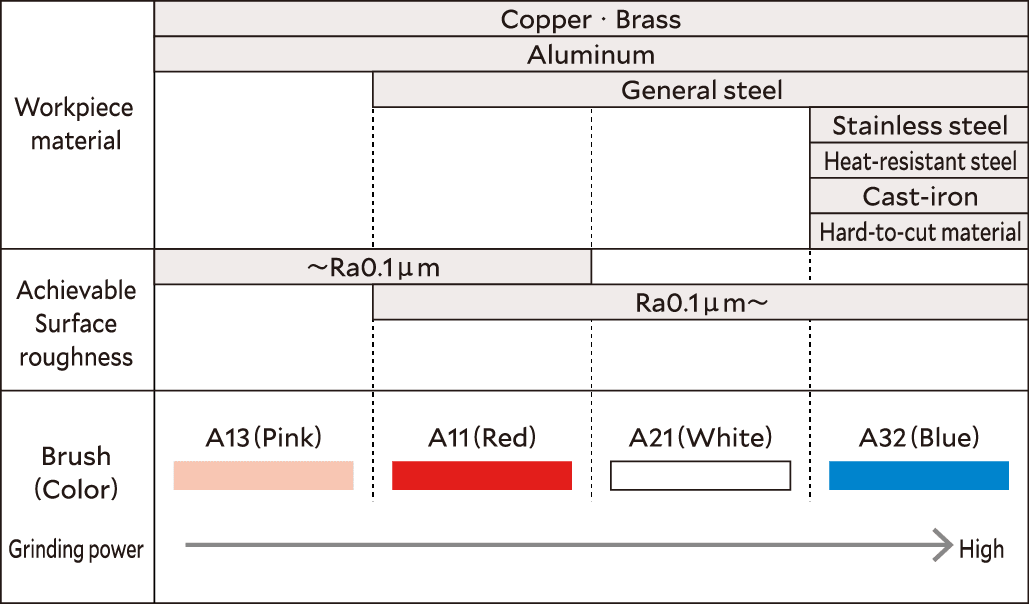

How to select Brush color

Select Brush color based on the workpiece material and burr root thickness.

Deburring

Cutter mark removal and polishing

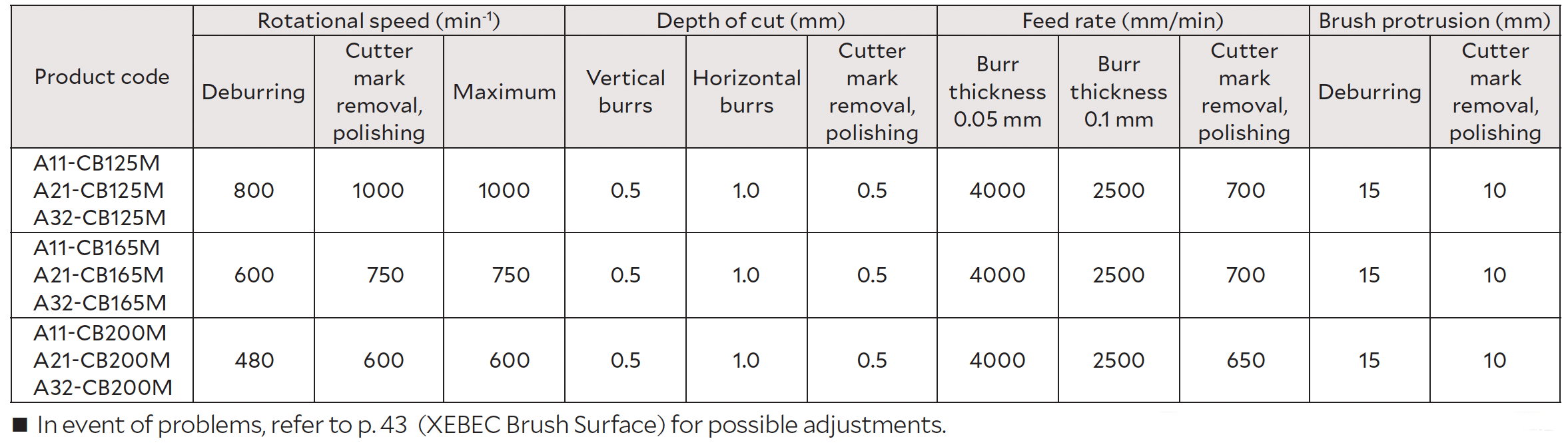

Starting parameters

How to adjust

If burrs remain

Increase the rotational speed to the maximum.

If burrs still remain, then decrease the feed rate.

For horizontal burrs, up cut is recommended so that the brush tip pushes up the burrs.

If the edge is too rounded

To make sharp edge, increase the feed rate in 1000mm/min increments within the range where burrs can be removed.

Increasing the feed rate also helps to reduce the cycle time.

Decrease the rotational speed in 10 to 20% increments within the range where burrs can be removed.

The grinding power of the Brush : Blue > White > Red

Select Brush color based on the workpiece material and burr root thickness.

To extend tool life

Increase the feed rate in 1,000mm/min increments within the range where burrs can be removed.

Decrease the rotational speed in 10 to 20% increments within the range where burrs can be removed.

If the surface becomes rough

Check the Brush color.

Change the Brush with higher edge quality.

Edge quality of the Brush: Red > White > Blue

Make sure to select appropriate Brush color based on the workpiece material and burr root thickness.

To improve surface roughness

Make sure to select appropriate Brush color.

Edge quality of the Brush : Red > White > Blue

The tool can be used for both dry and wet (oil-based and water-soluble) machining.

Wet machining may improve surface roughness and tool life.

When comparing in the same cycle time, increasing the number of passes makes bigger difference than decreasing feed rate.

Maintenance

Truing

When the brush is worn out unevenly, you can form the tip of the brush using a diamond disc blade.

Truing by a drilling machine

Truing by a lathe

If you want to cut off the brush, cut from the side of the brush using a diamond disc blade.

Operation safety measures

Always wear protective goggles, gloves and masks when operating the tool.

Wear long sleeved clothing and close the cuffs and outerwear sleeves to minimize skin exposure.

Cutting particles and burrs may scatter within an area around the work as the brush rotates.

Stay clear of this area.

Follow the precaution in use and safety measures for operators above without fail.

If you fail to observe them, there are following risks.

*A tool or a part of tool may crack, drop off, distort or break.

*Broken pieces of a tool or grinding dust may stick into your skin, or at worst stick into yours eyes, causing blindness.

*Dust generated by machining process may bring up skin irritancy or allergy.