XEBEC Burrless Chamfering Cutter

Burrless chamfering with a patented, multi-blade, V-shaped designXEBEC Burrless Chamfering Cutter™

Applicable equipment

This tool can be mounted on equipment shown below:

Machining center

Turn Mill Machine

Lathe (no live tooling)

Special machine

Robot

Rotary tool

(electric)

Rotary tool

(pneumatic)

About XEBEC Burrless Chamfering Cutter

A chamfering tool that does not generate burrs and therefore eliminates the need for another deburring process. This helps reduce the cycle time and tool costs.

Features

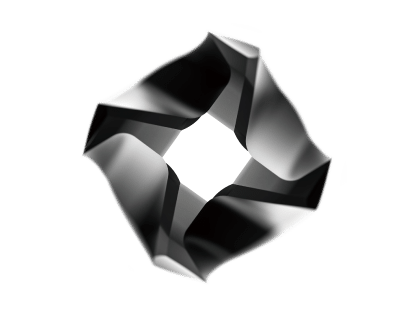

Patented V-shaped blade design

Unique design cuts a finished chamfer without secondary burrs. This eliminates the need for another deburring process.

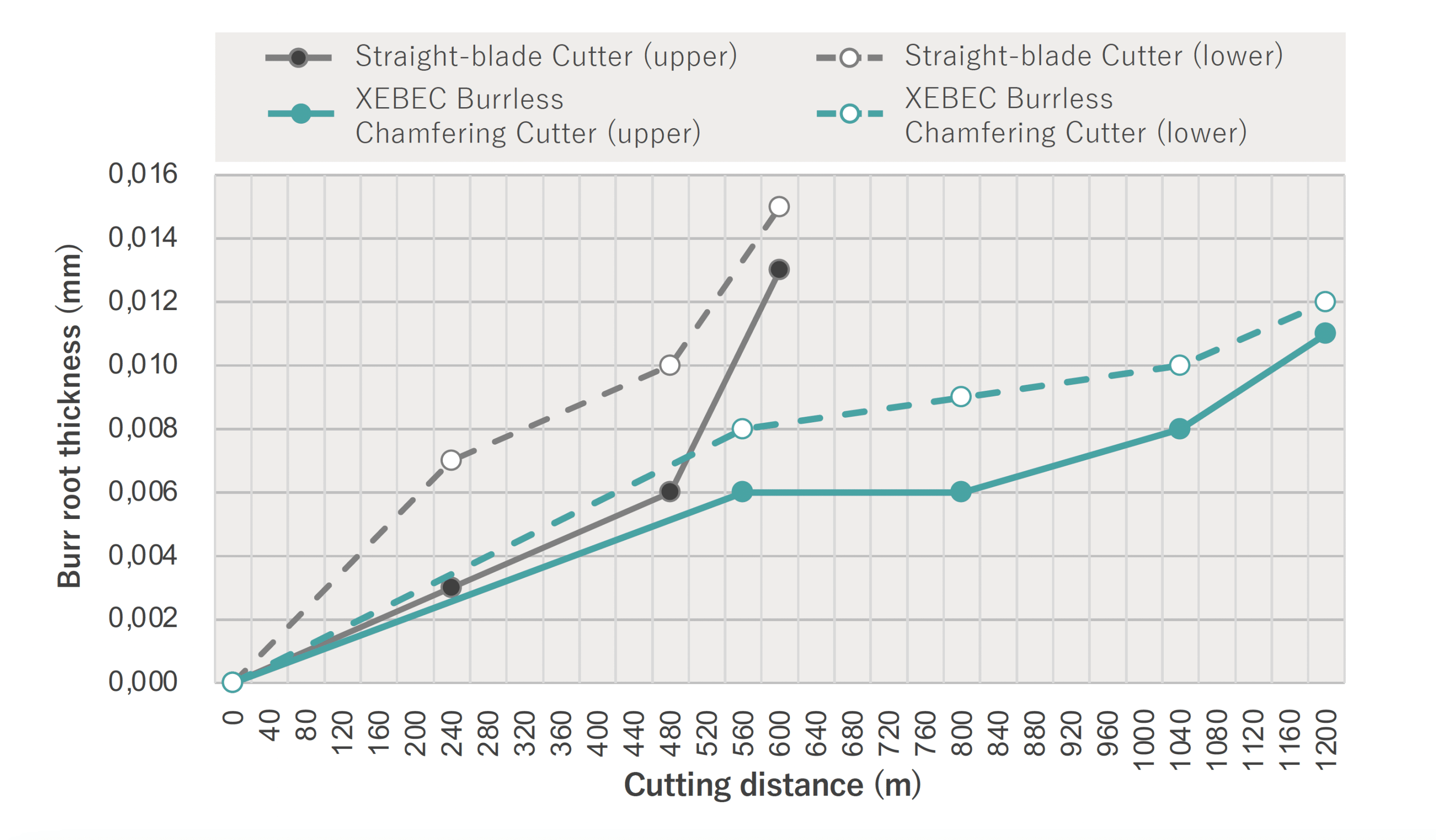

Twice longer tool life than a conventional chamfering cutter

Tests have shown that the tool life of this cutter is at least twice as long as that of a conventional chamfering cutter.

Multiple blades

Multi-blade design enables high feed rate. This reduces machining time for more efficient chamfering.

Flat tip

Ensures positional accuracy. The flat tip design prevents rounding and chipping that may cause tool length measurement errors.

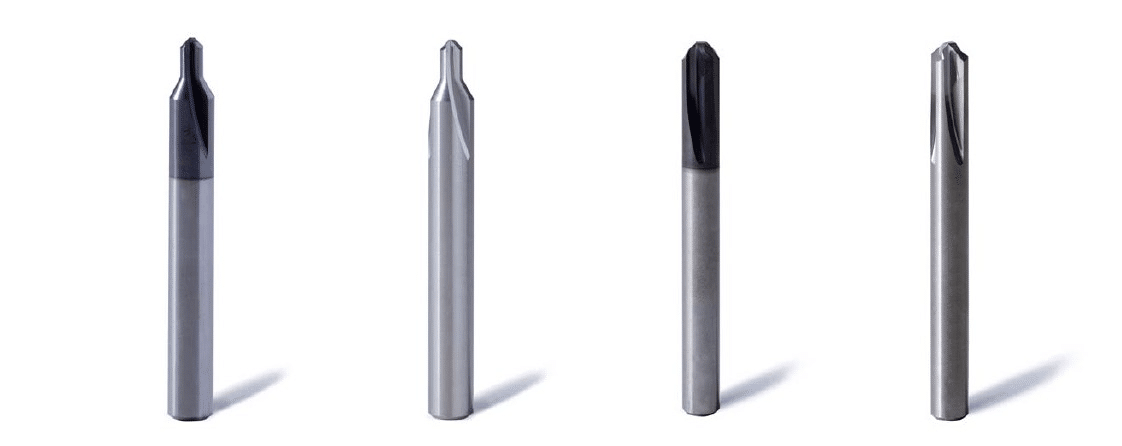

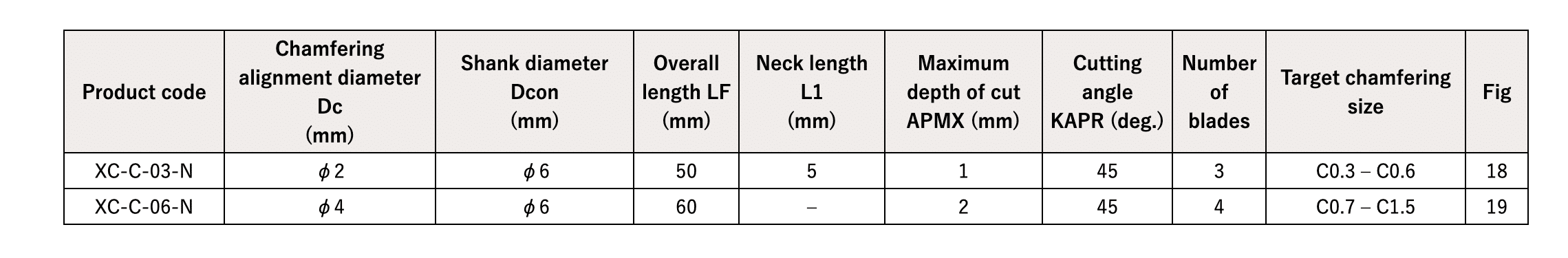

Specifications

AlTiCrN coated

Applicable materials: Steel P, stainless steel M, cast iron K, heat resistant alloy S, nonferrous metal N

Uncoated

Applicable materials: Nonferrous metal N, Resin O

Fig. 18

Fig. 19

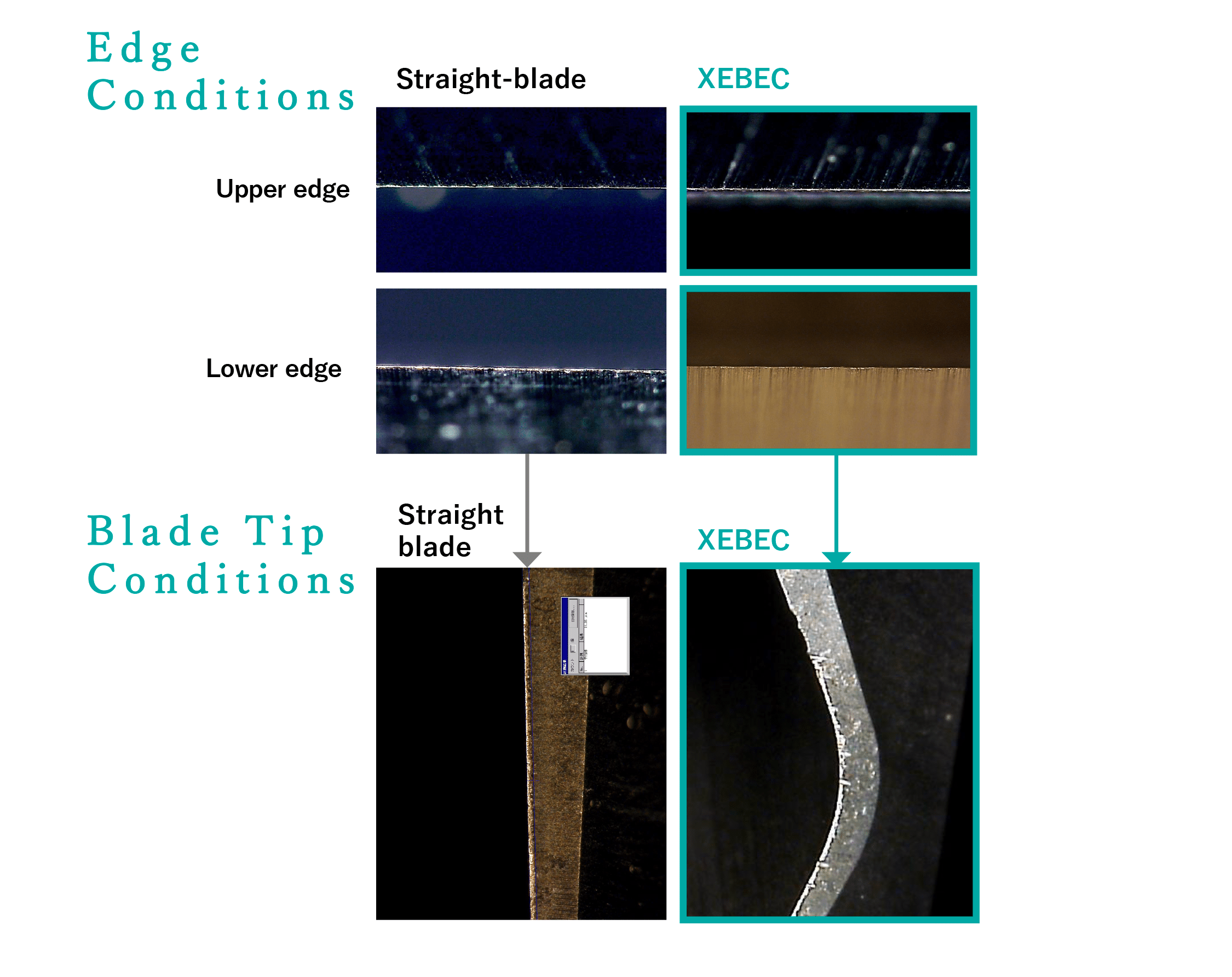

XEBEC vs . Straight – blade Cutter Upper Edge and Lower Edge

XEBEC vs . Straight – Blade Tool

*Photos compare the workpiece edge conditions after the tools have been used for the same cutting distance.

How to use

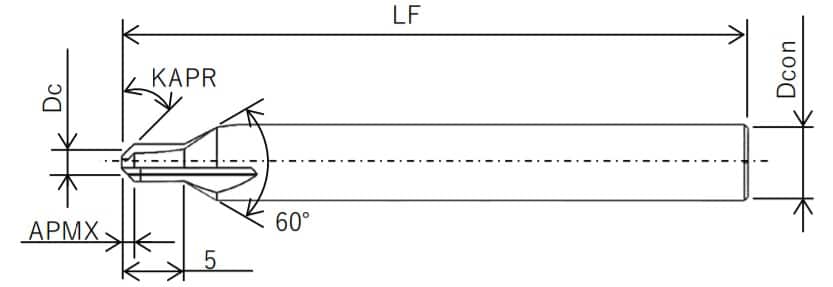

Position this tool so that Dc (Chamfering Alignment Diameter) is aligned with the

Chamfer Center Point. Dc (Chamfer Alignment Diameter) is the center of the Vshape

indicated by the red dot below.

Chamfer Size Adjustment Chart

Create the machining program by referring to Offsets A and B in the table below for desired chamfer size. This ensures Dc (Chamfer Alignment Diameter) and the Chamfer Center Point are aligned properly.

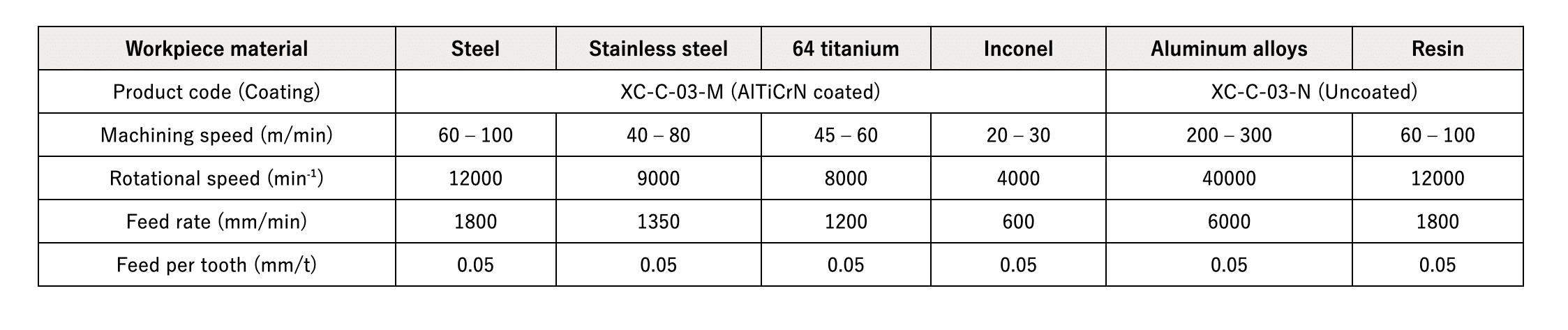

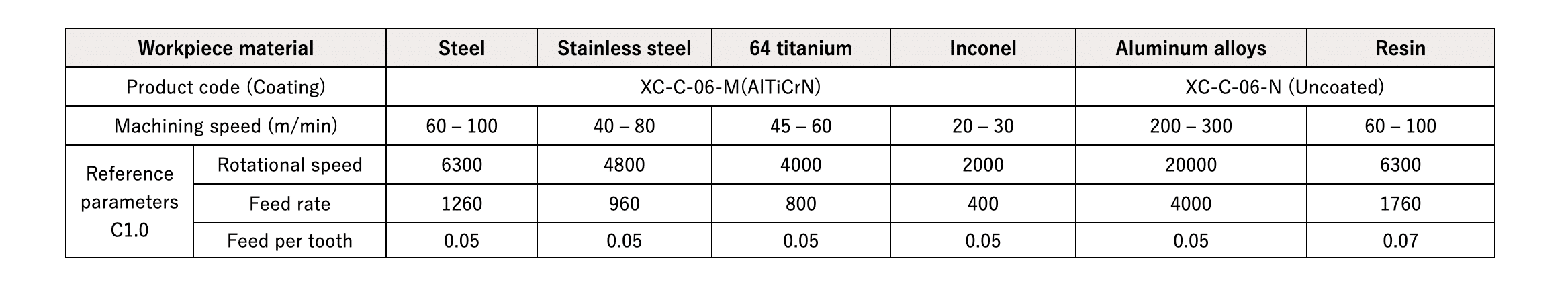

Machining Parameter

1. Rotational speed and feed rate are a guide for initial use.

2. To improve the machining result, take steps such as adjusting the rotational speed and feed rate, or try smaller chamfer sizes and increase them gradually to obtain the desired chamfer size.

3. If vibration or abnormal noise is detected, lower the rotational speed and feed rate, or try smaller chamfer sizes and increase them gradually to obtain the desired chamfer size.

4. If burrs are generated when machining plastics, maintain the feed per tooth at 0.07(mm/tooth) and use the same rotational speed as the tool you normally work with.

Product code: XC-C-03-M/N

Product code: XC-C-06-M/N

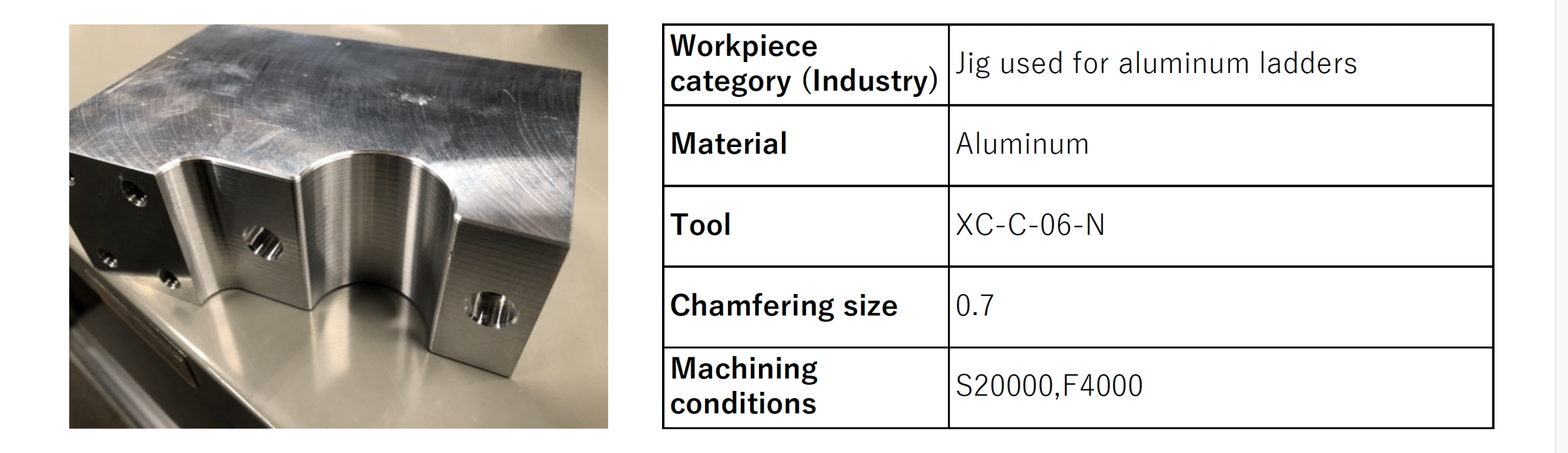

Applications

Burrless chamfering of fixturing jig

Holes were counter sunk and a belt sander was used on the circumferential edges for manual chamfering.

However, these tools caused secondary burrs. By using XEBEC Burrless Chamfering Cutter, the chamfering

time was reduced by 90% and the deburring process eliminated. This also resulted in tool cost reduction.

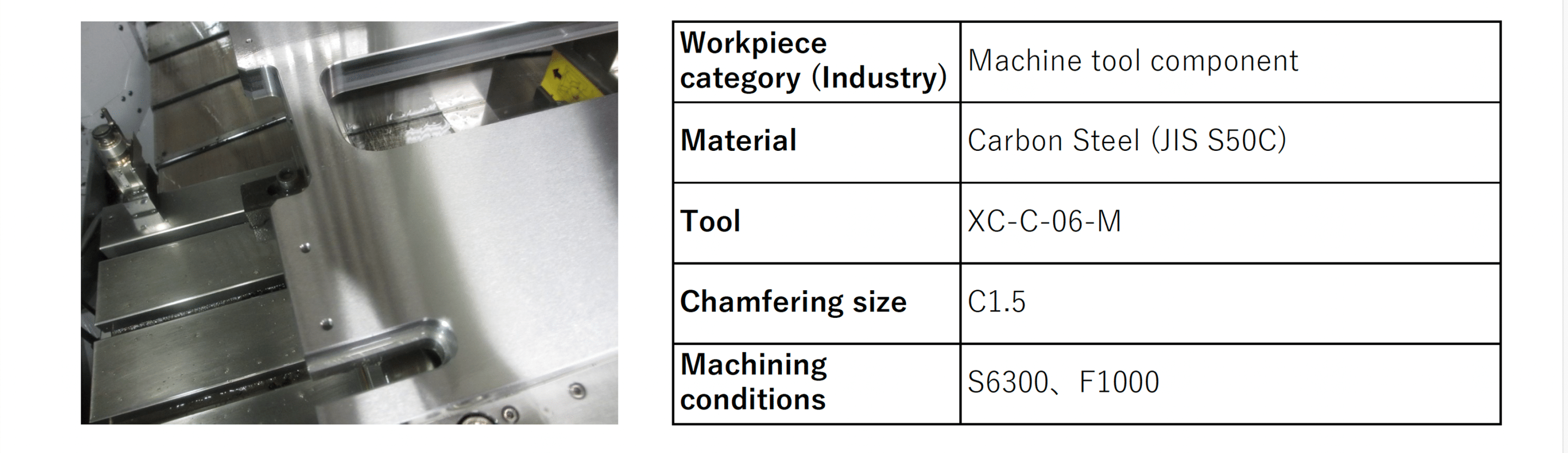

Burrless chamfering of machine tool component

It took about 5 minutes to remove secondary burrs from both front and back of the workpiece by hand with oil

stone after chamfering. This scratched the surface. With XEBEC Burrless Chamfering Cutter, the deburring

process was eliminated, and the finish result improved, without any scratch.

Burrless chamfering of cooling water block (Semiconductor manufacturing equipment)

The chamfering tool that was used previously caused secondary burrs, and manual deburring was needed after

chamfering. With XEBEC Burrless Chamfering Cutter, the chamfering time was reduced by 75% (from 60 to 15

seconds) and the deburring process eliminated.