XEBEC Stone™ Flexible Shaft

Flexible shaft allows soft contact with a workpiece and suppresses subtle vibration when being processed. Ideal for deburring both front and back of a drilled hole.

Applicable equipment

Machining center

Combined lathe

Special machine

Robot

Drilling machine

Rotary tool

(electric)

Rotary tool

(pneumatic)

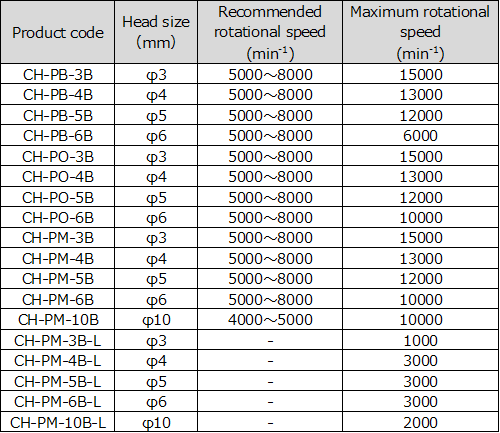

| Equivalent grit (Color) |

Product code | Head size (mm) |

Shaft diameter (mm) |

Shank diameter (mm) |

Overall length L (mm) |

Recommended rotational speed (min-1) |

Maximum rotational speed (min-1) |

Fig | |

| #800 (Blue) |

CH-PB-3B | φ3 | φ1.5 | φ3 | 70 | 5000~8000 | 15000 | 11 | |

| CH-PB-4B | φ4 | φ1.5 | φ3 | 70 | 5000~8000 | 13000 | 11 | ||

| CH-PB-5B | φ5 | φ1.5 | φ3 | 70 | 5000~8000 | 12000 | 11 | ||

| CH-PB-6B | φ6 | φ1.5 | φ3 | 70 | 5000~8000 | 10000 | 11 | ||

| #400 (Orange) |

CH-PO-3B | φ3 | φ1.5 | φ3 | 70 | 5000~8000 | 15000 | 11 | |

| CH-PO-4B | φ4 | φ1.5 | φ3 | 70 | 5000~8000 | 13000 | 11 | ||

| CH-PO-5B | φ5 | φ1.5 | φ3 | 70 | 5000~8000 | 12000 | 11 | ||

| CH-PO-6B | φ6 | φ1.5 | φ3 | 70 | 5000~8000 | 10000 | 11 | ||

| #220 (Gray) |

CH-PM-3B | φ3 | φ1.5 | φ3 | 70 | 5000~8000 | 15000 | 11 | |

| CH-PM-4B | φ4 | φ1.5 | φ3 | 70 | 5000~8000 | 13000 | 11 | ||

| CH-PM-5B | φ5 | φ1.5 | φ3 | 70 | 5000~8000 | 12000 | 11 | ||

| CH-PM-6B | φ6 | φ1.5 | φ3 | 70 | 5000~8000 | 10000 | 11 | ||

| CH-PM-10B | φ10 | φ1.5 | φ3 | 70 | 4000~5000 | 6000 | 11 | ||

| CH-PM-3B-L | φ3 | φ1.5 | φ3 | 150 | – | 1000 | 11 | ||

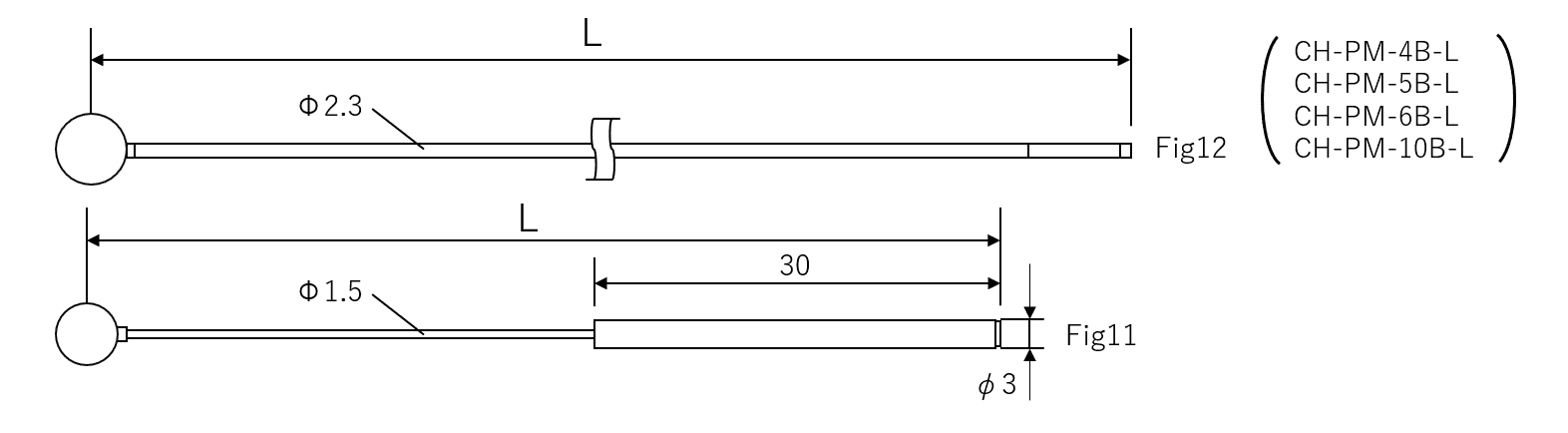

| CH-PM-4B-L | φ4 | φ2.3 | φ2.3 | 150 | – | 3000 | 12 | ||

| CH-PM-5B-L | φ5 | φ2.3 | φ2.3 | 150 | – | 3000 | 12 | ||

| CH-PM-6B-L | φ6 | φ2.3 | φ2.3 | 150 | – | 3000 | 12 | ||

| CH-PM-10B-L | φ10 | φ2.3 | φ2.3 | 150 | – | 2000 | 12 | ||

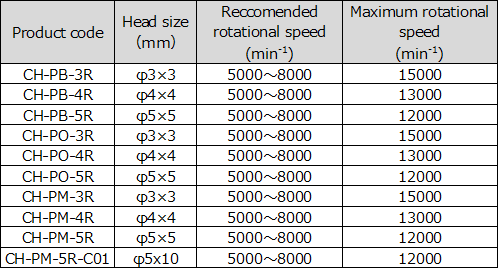

| Equivalent grit (Color) |

Product code | Head size (mm) |

Shaft diameter (mm) |

Shank diameter (mm) |

Overall length L (mm) |

Recommended rotational speed (min-1) |

Maximum rotational speed (min-1) |

Fig | |

| #800 (Blue) |

CH-PB-3R | φ3×3 | φ1.5 | φ3 | 70 | 5000~8000 | 15000 | 11 | |

| CH-PB-4R | φ4×4 | φ1.5 | φ3 | 70 | 5000~8000 | 13000 | 11 | ||

| CH-PB-5R | φ5×5 | φ1.5 | φ3 | 70 | 5000~8000 | 12000 | 11 | ||

| #400 (Orange) |

CH-PO-3R | φ3×3 | φ1.5 | φ3 | 70 | 5000~8000 | 15000 | 11 | |

| CH-PO-4R | φ4×4 | φ1.5 | φ3 | 70 | 5000~8000 | 13000 | 11 | ||

| CH-PO-5R | φ5×5 | φ1.5 | φ3 | 70 | 5000~8000 | 12000 | 11 | ||

| #220 (Gray) |

CH-PM-3R | φ3×3 | φ1.5 | φ3 | 70 | 5000~8000 | 15000 | 11 | |

| CH-PM-4R | φ4×4 | φ1.5 | φ3 | 70 | 5000~8000 | 13000 | 11 | ||

| CH-PM-5R | φ5×5 | φ1.5 | φ3 | 70 | 5000~8000 | 12000 | 11 | ||

| CH-PM-5R-C01 | φ5×10 | φ1.5 | φ3 | 70 | 5000~8000 | 12000 | 11 | ||

Precautions for use

The tool will be damaged when:

〇processed beyond the maximum rotation speed

〇used with a pneumatic tool

HOW TO USE

Precautions for use

*Usage over the maximum rotational speed may result in breakage of the head and shaft.

*The tool has high grinding power even at low rotational speed. Start from 1000min-1, and then gradually increase the rotational speed.

*Press lightly to the workpiece with approximately 1N (100gf, 0.5mm bending displacement), generally.

For effective use

Use the ball head size slightly larger than the edge size, and deburr by pressing the head against it.

Use the ball head type that is slightly smaller than the edge size, and deburr by contouring.

Use the cylinder-shaped head type and deburr by pressing it against the hole while moving it up and down.

Use the ball head type that is slightly larger than the groove width, and deburr by moving the head back and forth across the groove.

How to select

There are 5 diameter sizes: Φ3mm, Φ4mm, Φ5mm, Φ6mm and Φ10mm.

Two types of tip shape (ball type or cylinder type) are available.

For better surface roughness : #800

For higher grinding power : #220

Processing conditions

The tool has high grinding power even at low rotational speed.

Start from 1,000min-1, and then gradually increase the rotational speed.

The tool may break off when being processed beyond maximum rotational speed.

Never use at a rotational speed exceeding maximum rotational speed.

Ball type

Place the head lightly on the workpiece with approximately 1N (100g, bending displacement of 0.5mm), generally.

Start from 300mm/min. There is no upper limit of use.

Cylinder type

Maintenance

How to shape or form the tool tip

If the tip is worn out, form it with a diamond disc blade or grinder.

You can also customize the shape depending on the application or workpiece shape.

Operation safety measures

Always wear protective goggles, gloves and masks when using the tool.

Wear long sleeves, tight cuff, and clothing to minimize skin exposure.

Cutting particles and burrs may scatter within the work area as the tools rotates.

Please stay clear of the area.

The area around your work is hazardous in case flying pieces of fiber rods from the tools and grinding powder may scatter.

Enclose your working area to prevent other people from entering or have them wear protective equipment as well.

Follow the precautions for use and operation safety measures without fail.

If you fail to observe them, there are following risks.

*A tool or a part of tool may crack, drop off, distort or break.

*Broken pieces of a tool or grinding dust may stick into your skin, or at worst stick into yours eyes, causing loss of sight.

*Dust generated by machining process may bring up skin irritancy or allergy.